Kwang Leong Choy, Professor of Materials Science, Division of Natural and Applied Science, Duke Kunshan University

Professor Kwang Leong Choy has an extensive background in material science. With a D.Phil. in Material Science from the University of Oxford and a D.Sc. of Materials at the University of Nottingham. Professor Choy spent many years working in the world of material science. She has taken a series of academic roles such as faculty at Imperial College London, Chairperson in Materials and Director of the University Innovation Centre at the University of Nottingham, Director of the Institute for Material Discovery at University College London, before she landed on Duke Kunshan University now. Prof Choy is also working closely with colleagues to develop the Duke Kunshan University’s Phase III plan on Sustainability.

In this story, we will go into a journey with Prof Choy’s on how her expertise in material science intersects with sustainability.

Sustainability explained, in a practical way

Sustainability has been a highlighted keyword in recent years, but achieving sustainability requires solid progress made with well supported technological innovations together with social sciences, arts and humanities. As Prof Choy introduced, material science is one of the major disciplines that can push forward the technical foundation to achieve a long-lasting sustainability.

Thin film and coating is one of Prof Choy’s research focuses. Thin film and coating are widely used in the modern world, and are crucial parts in the manufacturing of common devices, coated components and equipment that people use. This is a multibillion-dollar industry that creates a broad spectrum of high-value added products. Therefore, any improvement in sustainability in this area will have extensive socio-economic and environmental impacts.

As an example, Prof Choy introduced how material science advancement in thin films and coatings contribute to sustainability. Electronic hardware and devices such as mobile phone touch screens, thin-film batteries, computer chips all require some kind of thin film parts in their making. Many other technologies also require some kind of coating to fulfil their specific requirements. For example, aeroplanes need protective coatings for their aero engines to function and reduce fuel consumption. Car surfaces need anti-corrosion, wear-resistant coatings to extend components’ service lifetimes. Prof. Choy reminds that this is also true for lots of emerging sustainable technologies: wind turbines need protective coatings to improve their life-expectancy and reduce maintenance; wastewater treatment needs special membranes for content separation; solar panels are also manufactured with layers of thin films and coatings.

Crafting sustainable materials and crafting materials sustainably

Prof Choy demonstrated two ways, for example, that material science can intersect with sustainability. Firstly, new materials can be designed, discovered and developed from earth abundant and/or renewable resources as well as to provide sustainability features, such as environmental friendly protective coatings onto wind turbine blades against corrosion, erosion etc. that can greatly improve its life-expectancy, minimise downtime, and drive down the maintenance cost. Secondly, improve the manufacturing technology to reduce energy consumption, the pollution discharged and the carbon footprint associated with the manufacturing process, and considering remanufacturing, recycling and reuse, making the product more eco-friendly.

One of Prof Choy’s research frontiers is looking at nature-inspired materials. In Prof Choy’s observation, nature is a fascinating manufacturer: it produces many products at ambient conditions, which means room temperature or moderate temperature, atmospheric pressure level, with efficient biosynthetic processes. In many cases, nature also makes foods and products out of human’s by-products or waste materials. Nature also creates unique texture and morphology for non-wetting surfaces.

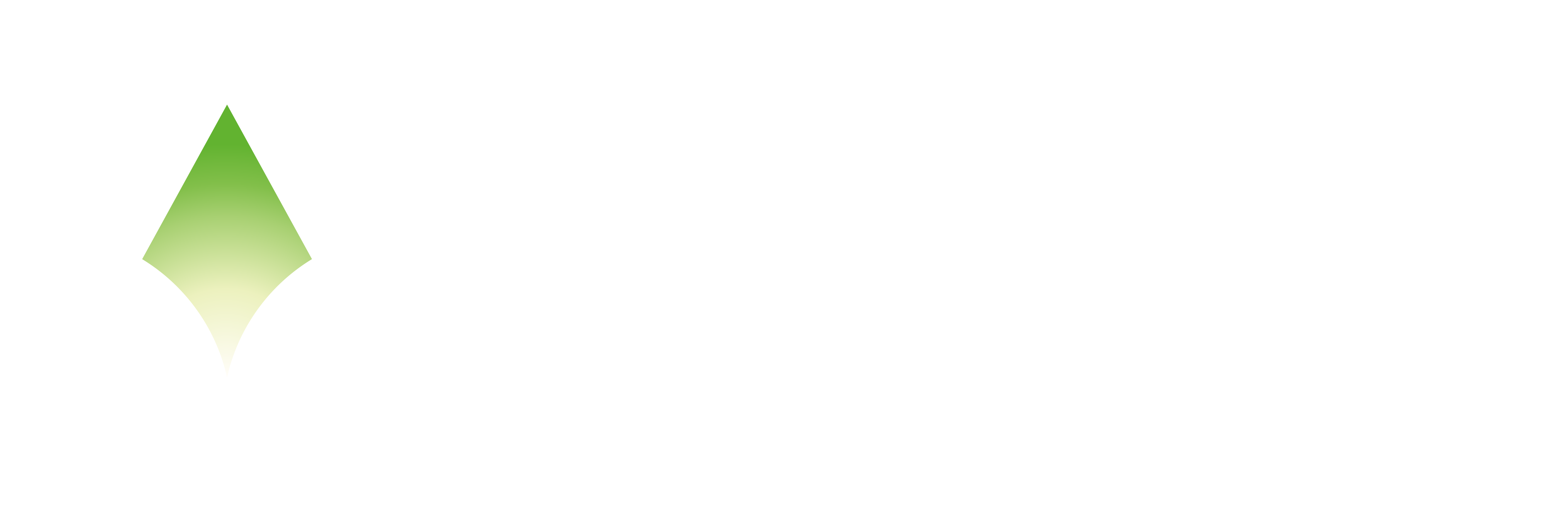

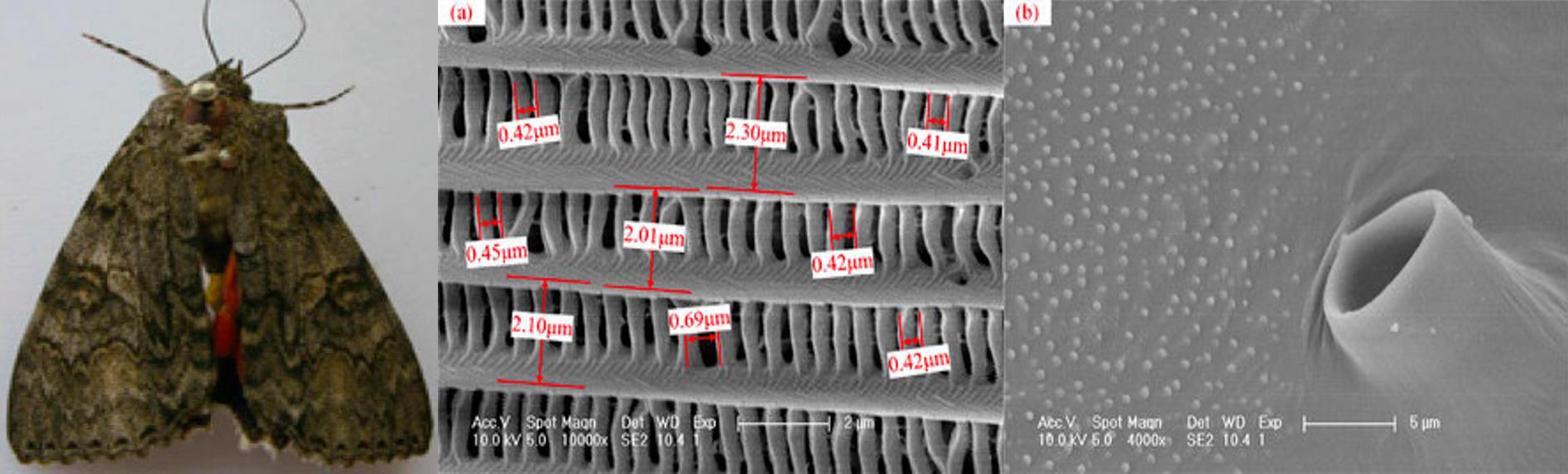

An example of Prof Choy’s research in this field is looking for (super)hydrophobic materials that can be used for anti-icing. Prof Choy looks for inspirations from species in nature, such as butterflies and lotus, as well as anti-frosting from moths.

Another major research highlight in Prof Choy’s portfolio is the sustainability improvement in the manufacturing process. In many years of her previous work, Prof Choy has made consistent progress in innovating the industrial thin film and coating processes in the manufacture pipelines, and has successfully brought the required temperature from several thousand Celsius degrees down to several hundreds, in some cases even to room temperature. This improvement can easily be translated into the decrease in energy consumption and associated carbon foot-print and emission. Across many years in this field, Prof Choy has filed around 20 patents, published over 300 related publications and also has plenty of technological transfers into the industry.

An ordinary day as a material scientist

Following the scientific achievement, Prof Choy also introduced what it looks like for a material scientist in her team.

Normally, there will be a material science problem that needs to be addressed. Once it’s defined, researchers will look into how to test the hypothesis. Quite often in the lab, researchers would try to formulate the precursors, such as mixing ingredients in a cocktail bar before using them to synthesise the materials. Generally, the produced material will be checked for its microstructure, phase, and composition just to ensure that the expected material is formulated and processed correctly.

Then, depending on the application of the material, the synthesized/processed material will go through a series of tests. For example, if the material will be applied on optical devices such as phone touch screens, its optical and electrical properties will be checked, such as the optical transparency and electrical conductivity. If the material is used for healthcare or biomedical scenarios, its biocompatibility will be evaluated. There are many other tests that are possible to be conducted in the lab, such as adhesion for film, abrasion/wear-resistance, corrosion-resistance etc. Sometimes the material also needs to be integrated into the actual product/device, such as batteries, before its energy-performance can be really tested.

In some occasions, Prof Choy’s team also conducts computer modelling to discover new materials, and simulate the materials processing and to predict the materials performance at the outset of the research, in the hope to bring down the number of experiments that needs to be done practically and reduce waste and the use of energy and resources .

“Makes a difference”

When asked about what motivates her to chase down this career path as a material scientist, Prof Choy said she “wants to make a difference”, The world around us nowadays is changing rapidly, there is a lot of growth and consumption, leading to increased energy use and pollution. “Therefore, there is a drive to protect our planet from global warming, conserving our natural resources, and then [understand] how we can live in harmony with nature and how we can provide a healthy and sustainable future for humanity.”

Prof Choy mentioned the Sustainable Development Goals (SDGs) raised by the UN, especially “Responsible consumption and production”, “affordable and clean energy”, “good health & wellbeing” and also “cleaning water and sanitization”[1]. Prof Choy sees her work pushing forward the progress and making a difference in these sustainability goals.

In Prof Choy’s own words: “At this stage of my career. I’m really passionate and keen to use my materials, skills, capabilities and expertise to see how I can contribute to addressing some of these global challenges. I also look forward to collaborating closely with like-minded DKU colleagues to address sustainability issues and create the desired and meaningful socio-economic and environmental impacts.

Source:Influence of wing scales of Catocala electa Borkhason on the frosting process, Choy and collaborators. https://www.tandfonline.com/doi/full/10.1080/16583655.2022.2042990

Source: Bionic Detectors Based on Low-Bandgap Inorganic Perovskite for Selective NIR-I Photon Detection and Imaging, Choy and collaborators. Advanced Materials https://onlinelibrary.wiley.com/doi/10.1002/adma.201905362 (2019)

Interviewer & writer: Liansai Dong